While traditional methods like welding and soldering are common for joining metal components, many high-reliability applications need a precise process that minimizes heat-induced distortion. That’s why our team from WessDel has highlighted the importance of advanced...

Advanced Materials & Machining

Advanced Aluminum Product Manufacturing: The AlBeMet Advantage

Traditional aluminum alloys have been reliable for decades, but critical applications in sectors like aerospace, defense, and semiconductor manufacturing require higher performance specifications that conventional metals cannot meet. As engineers pursue greater speed,...

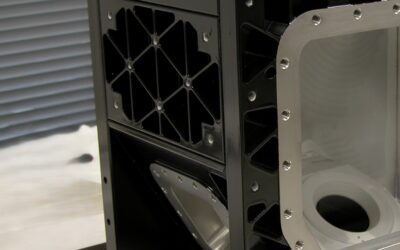

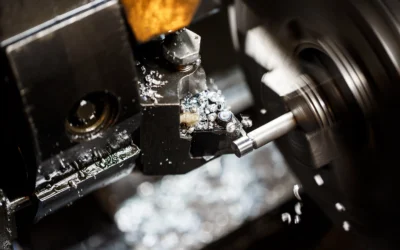

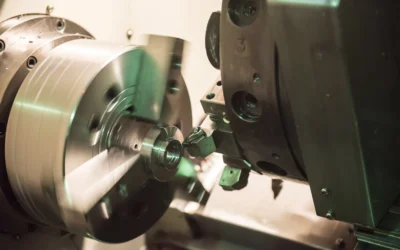

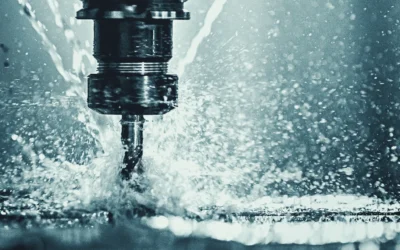

Advanced Precision Machining Demands for Exotic Materials

In aerospace, defense, optics, and other high-performance industries, components must meet extremely tight dimensional and functional requirements. When those components are made from titanium, beryllium, magnesium alloys, or other advanced materials, machining...

Precision Component Manufacturing: From Concept to Proof

In high-stakes engineering, whether aerospace, defense, or other mission-critical sectors, precision matters. Every micron, material choice, assembly step, and process decision can determine whether a part performs flawlessly under extreme conditions or fails when it...

Custom Machining Services that Scale from Prototype to Production

Precision manufacturing doesn’t end with a working prototype: it begins there. As projects move from proof of concept to production, every tolerance, process, and fixture must align to deliver consistent results at scale. This is especially important for industries...

Precision Machine and Manufacturing: Building for Zero Rework

In precision machining and manufacturing, zero rework is the standard for success. Rework wastes time and resources, especially in mission-critical industries like aerospace, defense, and medical, where failure is not an option. At WessDel, our entire culture is built...

Power Equipment Manufacturers: What to Demand from Precision Partners

For power equipment manufacturers, reliability is non-negotiable. In an industry where downtime can have severe consequences, every component must meet the highest standards of quality and precision. This is especially true for the precision components at the core of...

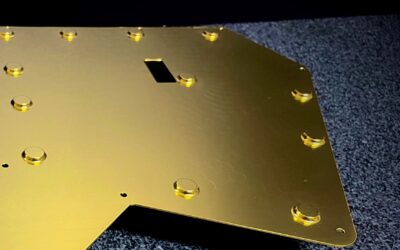

Aluminum and AlBeMet Product Manufacturing for High-Performance Systems

In aerospace and defense, aluminum offers light weight, machinability, and cost efficiency, but it can fall short in stiffness, vibration, or thermal stability. That’s when AlBeMet excels. WessDel’s expertise in aluminum product manufacturing and aluminum-beryllium...

The Role of Precision Metals in Clean Energy Innovation

Clean energy technologies are evolving rapidly, and precision energy products and metals are critical to their success. From hydrogen to wind and fusion, engineers rely on advanced materials and fabrication methods to meet demanding conditions. Precision Metals...

High‑Integrity Brazed Joints: Strategies for Advanced Materials & Complex Shapes

Brazing is essential in high-performance industries for creating strong, precise joints. But with advanced materials and complex designs, ensuring joint integrity is more challenging than ever. Let’s explore modern engineering strategies and emerging trends in brazing...