For power equipment manufacturers, reliability is non-negotiable. In an industry where downtime can have severe consequences, every component must meet the highest standards of quality and precision. This is especially true for the precision components at the core of...

Bob Dorricott

Engineering Consulting that De-Risks Manufacturability from Day One

In the world of high-stakes industries like aerospace, defense, and medical technology, the success of a project often hinges on decisions made in the earliest stages of design. However, a flawless design on paper can quickly become a costly and time-consuming...

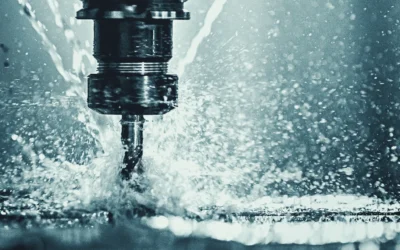

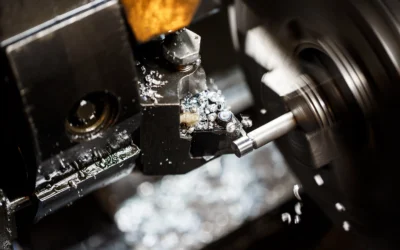

What Buyers Miss When Sourcing CNC Precision Machining Services

When sourcing CNC precision machining services, buyers often prioritize price and delivery. However, overlooking factors like capabilities, tolerances, and production processes can impact quality and success. This blog explores essential aspects to consider when...

Precision Brazing Services for Complex Mission‑Critical Assemblies

Brazing is essential for assembling complex parts in aerospace, defense, and electronics. Choosing the right brazing method affects the quality and performance of the final product. Let’s take a look at the various brazing processes, design considerations, compliance...

Aluminum and AlBeMet Product Manufacturing for High-Performance Systems

In aerospace and defense, aluminum offers light weight, machinability, and cost efficiency, but it can fall short in stiffness, vibration, or thermal stability. That’s when AlBeMet excels. WessDel’s expertise in aluminum product manufacturing and aluminum-beryllium...

Aerospace CNC Machining: From Ready Designs to Flight Hardware

Aerospace CNC machining is where engineering precision meets the unforgiving demands of flight. Turning a qualification-ready design into hardware capable of withstanding extreme conditions requires more than cutting metal, it demands a disciplined approach to...

The Role of Precision Metals in Clean Energy Innovation

Clean energy technologies are evolving rapidly, and precision energy products and metals are critical to their success. From hydrogen to wind and fusion, engineers rely on advanced materials and fabrication methods to meet demanding conditions. Precision Metals...

High‑Integrity Brazed Joints: Strategies for Advanced Materials & Complex Shapes

Brazing is essential in high-performance industries for creating strong, precise joints. But with advanced materials and complex designs, ensuring joint integrity is more challenging than ever. Let’s explore modern engineering strategies and emerging trends in brazing...

Future of Aluminium: Innovations in Alloys & Machining

Aluminum is evolving into a key material for industries that demand strength, precision, and thermal stability. As performance requirements rise, WessDel leads with advanced alloys in aluminum product manufacturing, precision machining, and innovative solutions to...

Specialized CNC Machining: Speed, Materials & Resilience

Engineering teams in high-tech sectors face tight timelines, demanding tolerances, and nonstop innovation pressure. Relying solely on internal machining limits agility. Leading companies are partnering with specialized CNC shops to access advanced capabilities and CNC...