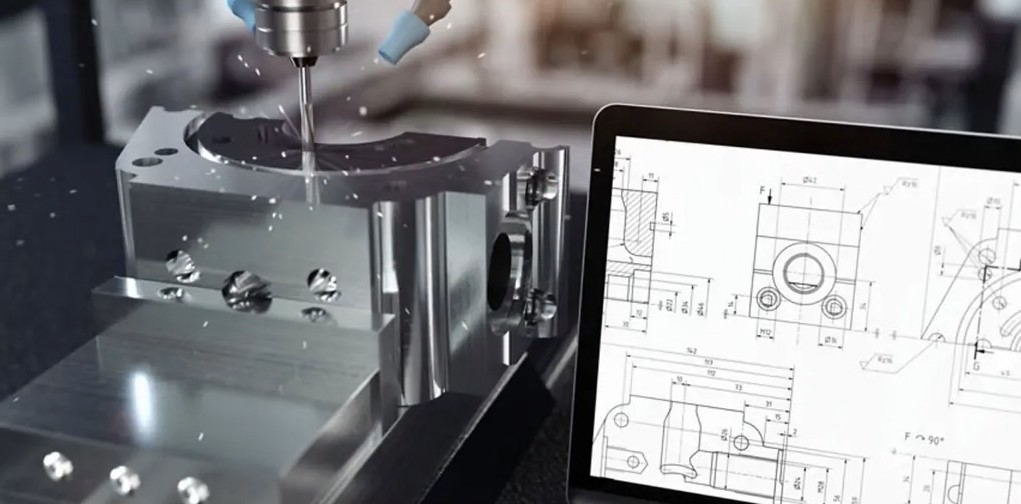

Aerospace CNC machining is where engineering precision meets the unforgiving demands of flight. Turning a qualification-ready design into hardware capable of withstanding extreme conditions requires more than cutting metal, it demands a disciplined approach to quality, materials, tolerance, and process control. From spacecraft components to military aircraft systems, every detail matters.

Standards That Drive Aerospace CNC Quality

In aerospace manufacturing, quality standards define the path from design approval to certified flight hardware. A foundation built on AS9102 first article inspection (FAI) ensures every component is traceable and documented before production begins. Early verification of special processes, such as coatings or heat treatments, along with supplier qualification, prevents delays later in the program.

Equally important is configuration management. Aerospace projects often undergo mid-program design updates, and without rigorous controls, mismatched revisions can jeopardize entire assemblies. An APQP-style planning approach makes these transitions manageable by embedding quality checks into every stage of the build.

Materials and Machinability for Flight Components

Components must balance strength, heat resistance, and dimensional stability while still being manufacturable. Titanium offers unmatched strength-to-weight performance, while high-purity aluminum is favored for lightweight structural parts. Alloys like Inconel and Invar are essential for high-heat environments or applications where thermal expansion must be tightly controlled.

Machining these materials requires specialized strategies. Thin-wall sections can distort under tool pressure, and residual stress can cause unexpected warping. In cases where conventional tools may induce burrs or movement, electrical discharge machining (EDM) is often the better choice to achieve tight, burr-free features.

Tolerance Strategy for Harsh Environments

Unlike many industries, aerospace tolerances must survive extremes of vibration, pressure, and temperature. This is where geometric dimensioning and tolerancing (GD&T) becomes indispensable. Properly applied GD&T ensures parts remain functional even when exposed to thermal cycling at altitude or the constant vibration of jet engines.

Complex assemblies, whether bolted, brazed, or mounted kinematically, require stack-up analysis to predict how small variations add up across multiple components. To validate precision, CMM (coordinate measuring machine) programs replicate real-world datum conditions, ensuring that every measurement aligns with how the part will perform in service.

WessDel’s Aerospace CNC Machining Advantage

At WessDel, aerospace machining is a specialty refined through years of experience. With advanced multi-axis CNC milling and turning, EDM, and waterjet capabilities, WessDel supports both aircraft systems and spacecraft structures. Every part is produced under the strict framework of AS9100D and ISO 9001:2015 quality systems, ensuring compliance with the highest industry standards.

The team’s experience spans commercial and defense applications, from high-precision components to complex brazed structures. WessDel’s consistent track record makes it a trusted partner among aerospace machining companies.

Contact WessDel for Aerospace CNC Machining

Transforming bold designs into flight-ready hardware requires a partner who lives and breathes aerospace precision. From prototypes to mission-critical production, WessDel delivers unmatched accuracy, reliability, and compliance in aerospace CNC machining every step of the way. Ready to launch your next project?

Contact WessDel and build with confidence.