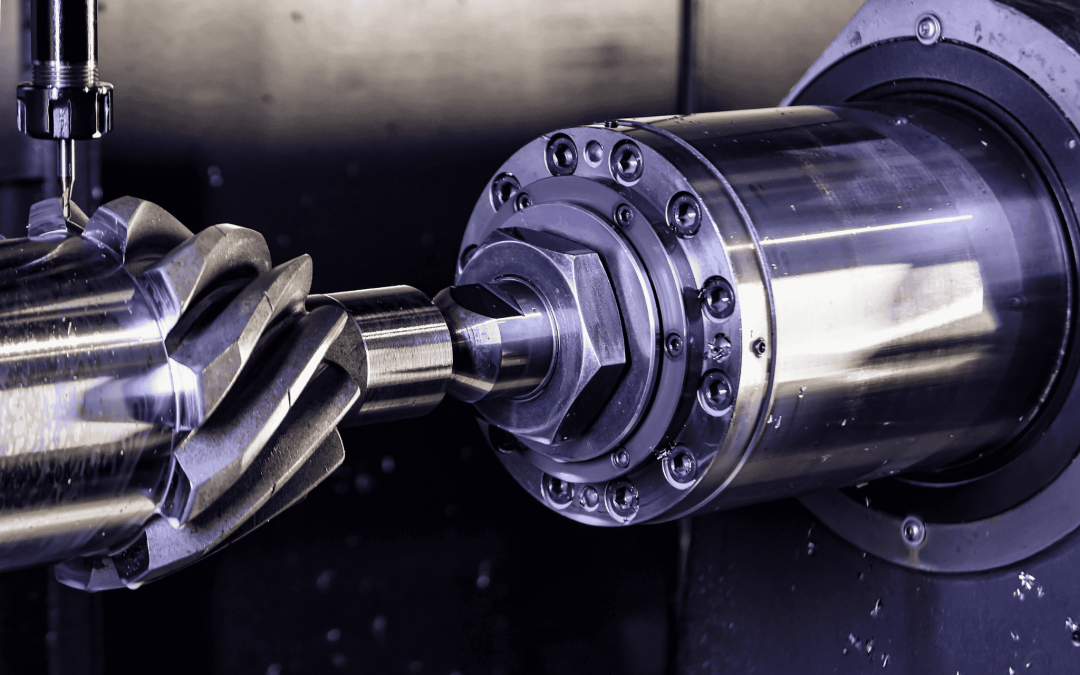

Precision machining enables the production of intricate components that meet exact specifications in demanding environments. At WessDel, we specialize in delivering high-precision parts for industries where failure is not an option. Our advanced precision machining and manufacturing capabilities support innovation, reliability, and performance from aerospace and defense to semiconductors and energy.

Aerospace: Engineering the Future of Flight and Exploration

Aerospace applications demand components that can withstand extreme conditions while maintaining flawless performance. At WessDel, we manufacture flight-critical parts with ultra-tight tolerances and complex geometries, essential for aircraft engines, aerostructures, and space-bound systems.

Our expertise includes machining advanced aerospace materials such as titanium, Inconel, and beryllium—key for achieving lightweight designs, high heat resistance, and durability. We leverage advanced technologies like 5-axis CNC machining, electrical discharge machining (EDM), and digital manufacturing tools to produce next-generation aerospace components that meet the industry’s evolving challenges.

Defense: Precision for National Security and Technological Supremacy

WessDel supports national security initiatives by machining parts for advanced weaponry, surveillance systems, armored vehicles, and guidance equipment with uncompromising accuracy and reliability.

We work with defense-grade materials, including hardened steels and ballistic alloys, to ensure parts perform in the harshest operational environments. Our agile manufacturing capabilities also allow us to respond quickly to emerging threats with rapid prototyping and low-to-mid volume production of cutting-edge defense technologies.

Semiconductors: Enabling the Next Wave of Technological Advancement

The semiconductor industry demands machining at microscopic levels to support the production of increasingly powerful and compact electronic devices. WessDel delivers ultra-precision components in wafer handling systems, vacuum chambers, and precision tooling with sub-micron accuracy and flawless surface finishes.

We are skilled in machining challenging materials such as quartz, high-purity aluminum, advanced ceramics, and specialized polymers—essential for stability and performance in cleanroom and high-vacuum environments.

Energy: Powering the Present and Building a Sustainable Future

From traditional power generation to renewable energy systems, the energy sector relies on robust, high-performance components that endure punishing conditions. WessDel produces precision-machined parts for turbines, oil and gas systems, and nuclear power applications that must withstand high pressures, corrosive environments, and extreme temperatures.

We also support the growing renewable energy market by machining components for wind turbines, solar manufacturing equipment, and advanced energy storage systems. Our materials expertise—from stainless steel to corrosion-resistant alloys—ensures safety, reliability, and long-term durability in mission-critical energy applications.

Medical Devices: Precision for Life-Saving Technologies

While not our primary focus, WessDel supports the medical industry by machining intricate, biocompatible components for surgical tools, orthopedic implants, and diagnostic equipment. We work with materials like titanium and PEEK, following stringent quality control standards to ensure compliance with FDA and ISO 13485 regulations.

Our micro-machining and CNC technology capabilities also support the trend toward smaller, more advanced medical devices, including components for minimally invasive procedures and next-gen diagnostic platforms.

Contact WessDel for Precision Machine and Manufacturing

Every part we craft at WessDel powers something bigger—jet engines, defense systems, next-gen tech. With decades of expertise and cutting-edge tools, we deliver precision that performs.

Ready to discuss your project? Contact WessDel today to learn how our precision machining and manufacturing services can support your industry’s toughest challenges.