The Signs of a Professional Titanium CNC Machining Services Provider

Titanium is a material prized for its exceptional strength-to-weight ratio and resistance to corrosion, making it crucial for demanding applications in aerospace, defense, medical, and semiconductor industries. Its inherent hardness and thermal properties present unique machining challenges. Identifying a professional titanium CNC machining services provider will help ensure your critical components’ precision, quality, and reliability.

Specialized Expertise and Experience

A hallmark of a professional titanium CNC machining service is its deep understanding and extensive experience working with this material. They will have advanced techniques honed over years of tackling titanium’s machining complexities. Providers like WessDel, with nearly 50 years in precision machining, demonstrate this specialized expertise, which is particularly valuable in high-stakes industries.

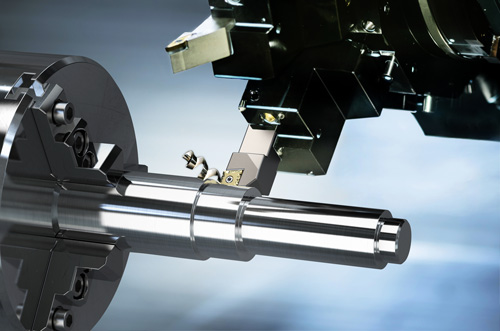

Advanced Machining Capabilities

Working with titanium demands sophisticated equipment and processes. A professional provider will utilize cutting-edge CNC machining centers, including multi-axis milling (4-axis and 5-axis), turning centers, waterjet cutting, and electrical discharge machining (EDM). These technologies allow for intricate designs and the tight tolerances required for titanium components. WessDel’s state-of-the-art, temperature-controlled 24,000-square-foot facility exemplifies this commitment to advanced capabilities.

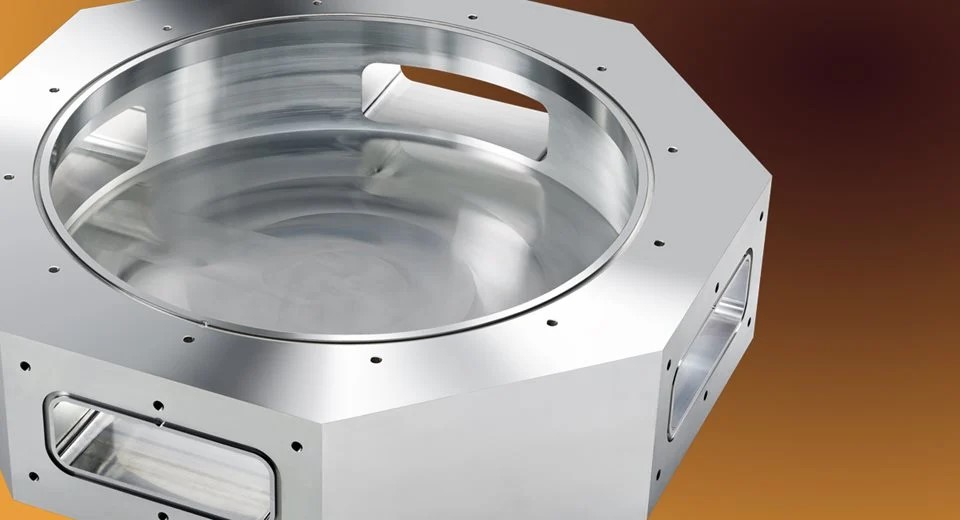

Focus on Precision and Quality Standards

In industries where titanium components are mission-critical, precision and quality are non-negotiable. A professional machining service adheres to stringent industry standards such as ANSI, ASME, ASTM, Mil-Spec, and RoHS compliance. Furthermore, certifications like AS9100D and ISO 9001:2015 demonstrate a commitment to consistent quality control throughout their operations. WessDel’s dedication to achieving tolerances as precise as 0.0002 inches underscores this focus.

Tailored Solutions and Collaborative Engineering

Complex projects involving titanium benefit from early collaboration between the customer and the machining provider. A professional service offers concurrent engineering support, working with clients during the design phase to ensure manufacturability and optimize component performance. This proactive approach is crucial for mission-critical applications where failure is not an option. WessDel’s customized solutions for complex projects highlight this collaborative spirit.

Commitment to High-Performance Industries

A professional titanium CNC machining provider understands the unique demands of industries that rely on titanium’s properties. We tailor our processes and expertise to meet the stringent requirements of aerospace, defense, semiconductor, and medical sectors. Our ability to handle prototyping and full-scale production makes us valuable partners. WessDel’s focus on these high-performance industries demonstrates this alignment.

Innovative Manufacturing Practices

Efficiency and quality go hand-in-hand in professional machining. Providers that implement lean manufacturing techniques and advanced process controls ensure both. A commitment to innovation, including exploring new machining techniques to overcome the challenges associated with titanium, further distinguishes a top-tier service. WessDel’s dedication to innovative manufacturing practices reflects this forward-thinking approach.

Titanium Machining FAQs

Contact WessDel For Titanium CNC Machining Services

Ready to unlock the full potential of your titanium CNC machining projects? WessDel has been pushing the boundaries of precision with state-of-the-art equipment and has had an unwavering dedication to quality for nearly half a century. Let’s bring your most challenging designs to life. Contact WessDel online today or call (408) 496-6822