Machining Exotic Materials & Alloys

Materials like beryllium, aluminum-beryllium alloys (AlBeMet), Invar, Inconel, and titanium offer unique properties needed for aerospace, defense, semiconductor, and medical applications. However, machining these materials creates challenges due to cost, abrasiveness, and sensitivity. Here’s how to select an exotic metal machining services provider with the necessary expertise and equipment for your project.

Evaluating Potential Partners: Key Considerations

When searching for an exotic metal machining service provider, evaluate several factors carefully:

Specialized Expertise

Does the provider have a proven track record working with the specific exotic materials your project requires? Look for companies that highlight their specialization and experience with materials like beryllium and AlBeMet, which demand unique handling and machining techniques.

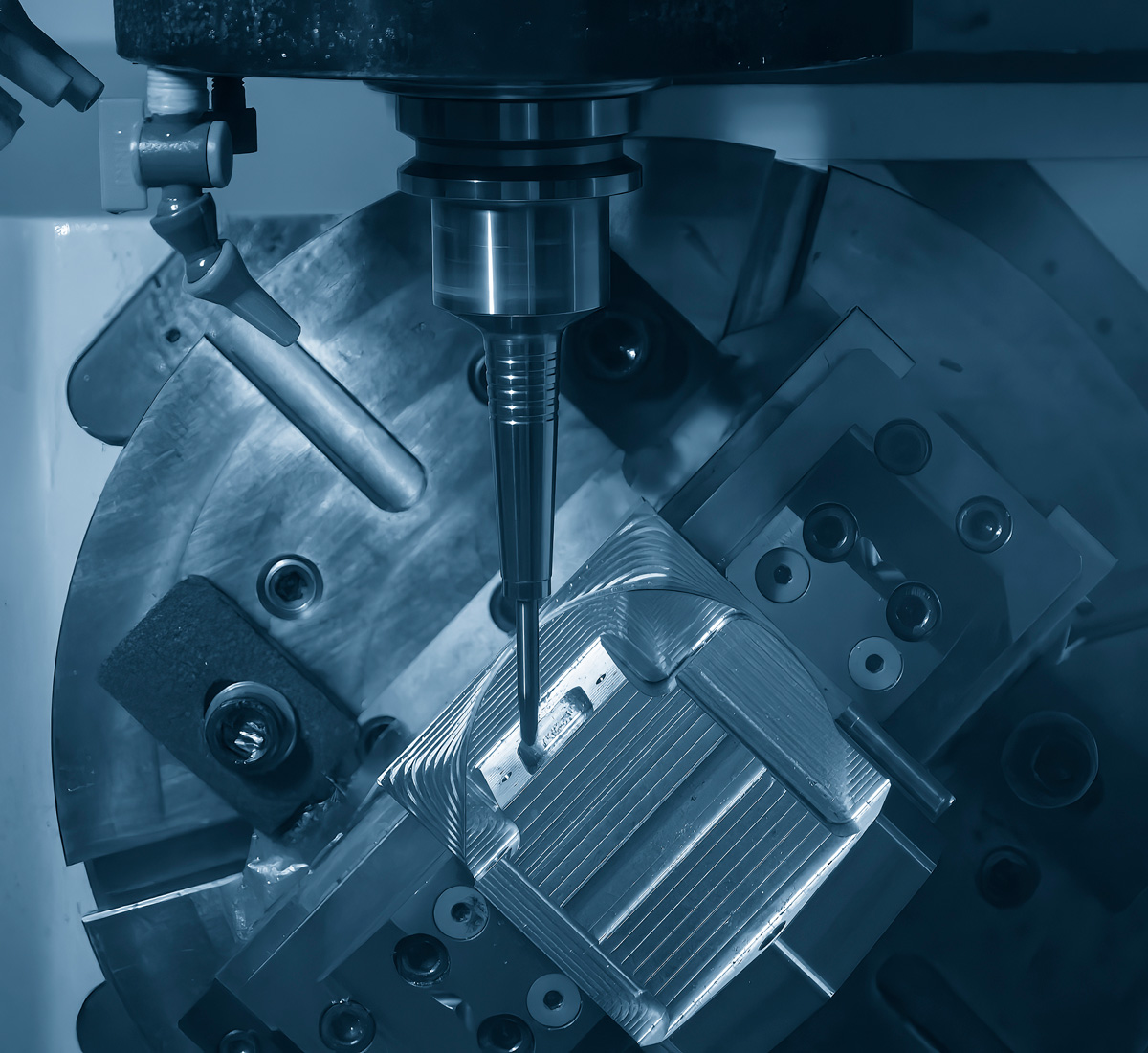

Advanced Technological Capabilities

Ensure the provider utilizes state-of-the-art equipment capable of handling the complexities of exotic metals, including advanced CNC machining centers (three, four, and five-axis), EDM machines, and waterjet cutting. These technologies enable the precision and complex geometries often required for high-performance applications.

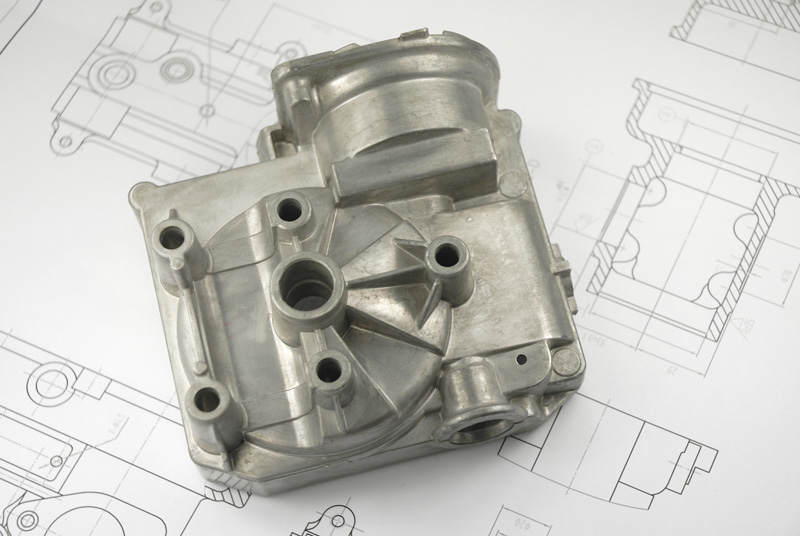

Commitment to Precision and Quality

Verify the provider’s ability to meet stringent tolerances. Achieving tolerances within ten-thousandths of an inch is often necessary for critical applications. Look for certifications like AS9100D and ISO 9001:2015, which indicate adherence to rigorous quality management systems.

Safety Protocols

Machining exotic materials, particularly beryllium, requires strict adherence to safety regulations. The provider should have robust engineering controls, such as negative pressure systems with HEPA filtration, to ensure worker safety and environmental compliance.

Industry Recognition and Experience

A long history of successful projects within demanding industries like aerospace and defense strongly indicates reliability and expertise. Consider providers with a well-established reputation as trusted suppliers for mission-critical components.

Comprehensive Service Offering

Determine if the provider can support your project from prototyping through full-scale production. Flexibility and the ability to offer tailored solutions are important considerations.

Facility Infrastructure

A well-equipped and controlled environment is crucial for maintaining the integrity of exotic materials during machining. Look for providers operating out of modern, temperature-controlled facilities.

Why Specialization Matters

Choosing a provider with expertise means they have developed the necessary techniques and invested in equipment optimized for their unique properties.

This specialization translates to:

Reduced Material Waste

Expertise in handling costly exotic metals minimizes errors and waste.

Improved Part Quality

Specialized processes prevent microfractures and achieve tight tolerances.

Enhanced Tool Life

Experienced machinists utilize techniques to extend the life of specialized cutting tools.

Increased Efficiency

Streamlined processes tailored to specific materials can lead to faster turnaround times.

Contact WessDel For Exotic Metal Machining Services

For nearly 50 years, WessDel has mastered precision machining of exotic metals like beryllium and titanium for critical industries. Our advanced facility and certifications ensure top quality. Partner with us for your demanding aerospace, defense, semiconductor, and medical projects and exotic metal Machining. Contact WessDel online today or call (408) 496-6822 – we’re ready to get started.