How WessDel’s Expertise as a Brazing Supplier Supports Your Business

Brazing is an essential process in precision manufacturing, and choosing the right supplier is the first step for every project. WessDel offers extensive expertise in brazing, providing a comprehensive suite of services designed to meet the demanding requirements of various industries. Our proficiency as brazing suppliers directly supports your business by ensuring high-quality, reliable joining solutions for complex components and assemblies.

Customized Brazing Services

Our service portfolio includes:

Controlled Atmosphere Brazing

This precise method is conducted in a controlled gas environment, guaranteeing optimal joint integrity and minimizing oxidation.

Dip Brazing

Particularly effective for aluminum and similar materials, dip brazing involves immersing parts in molten flux, resulting in strong and consistent bonds.

Furnace Brazing

Our high-temperature furnace ensures uniform and dependable joints for intricate assemblies.

Vacuum Brazing

Conducted in a vacuum chamber, this clean process prevents oxidation and is ideal for high-performance applications where material purity is paramount.

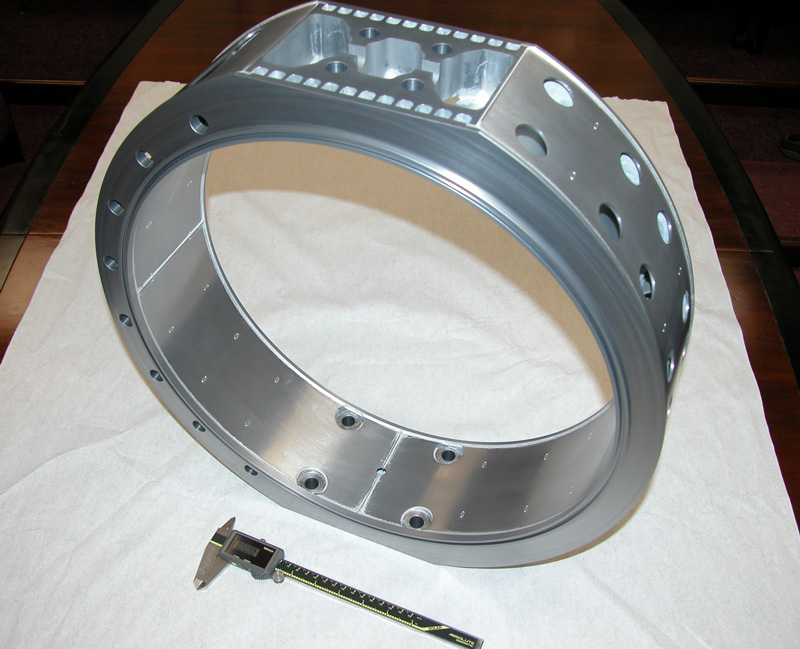

These processes can accommodate components with dimensions up to 48 inches in length and diameter, providing flexibility for various projects.

Adherence to Stringent Industry Standards

Quality and compliance are at the forefront of WessDel’s brazing operations. Our services adhere to rigorous industry standards, including ANSI, ASME, ASTM, AWS, Mil-Spec, and RoHS. This commitment ensures that our brazed components meet the stringent requirements of the aerospace, defense, semiconductor, and medical industries. Our AS9100D and ISO 9001:2015 certifications further underscore our dedication to maintaining the highest quality management systems.

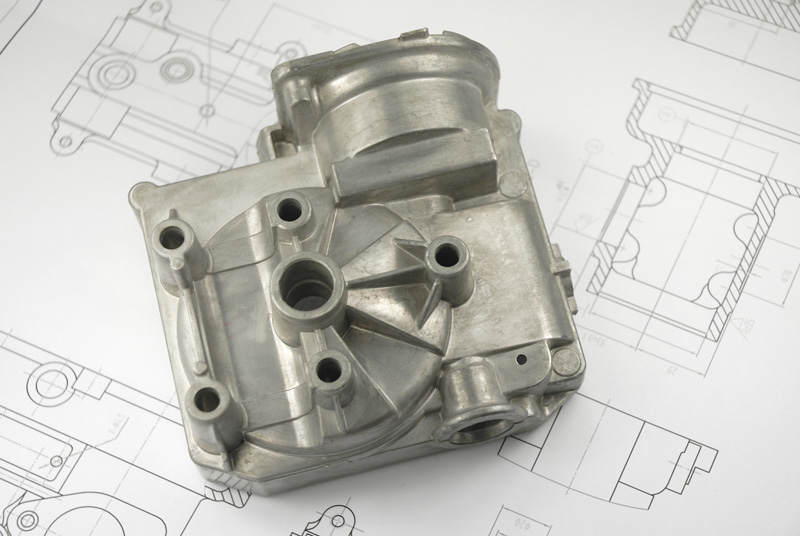

Expertise with Advanced Materials

WessDel works with advanced materials, including beryllium and aluminum beryllium (AlBeMet). Our expertise in brazing these materials enables the production of complex and high-performance components. A notable example of our capabilities is our involvement in the NPOESS NASA program, where we produced instrument frames for environmental science applications. Additionally, for the US Space Force SBIRS programs, WessDel created brazed structures from individual Beryllium parts using advanced CNC milling, wire EDM, and state-of-the-art brazing processes. Our approach matched or exceeded the strength of monolithic structures and offered significant cost advantages.

Supporting Mission-Critical Applications

WessDel’s brazing expertise is crucial for mission-critical applications where precision and reliability are non-negotiable. By integrating advanced manufacturing techniques with strict quality control measures, we consistently deliver high-performance brazing solutions that meet the demanding needs of our clients. Our track record in demanding sectors demonstrates our capability to handle complex projects requiring exceptional precision and durability.

Contact WessDel to Speak with a Leading Brazing Supplier

Ready to elevate your manufacturing? WessDel’s got the brazing know-how you need for those mission-critical projects. We’re passionate about always getting it right, with even the trickiest materials. Let’s talk about how our expertise as brazing suppliers can make a real difference for you. Contact WessDel online today or call (408) 496-6822 today!