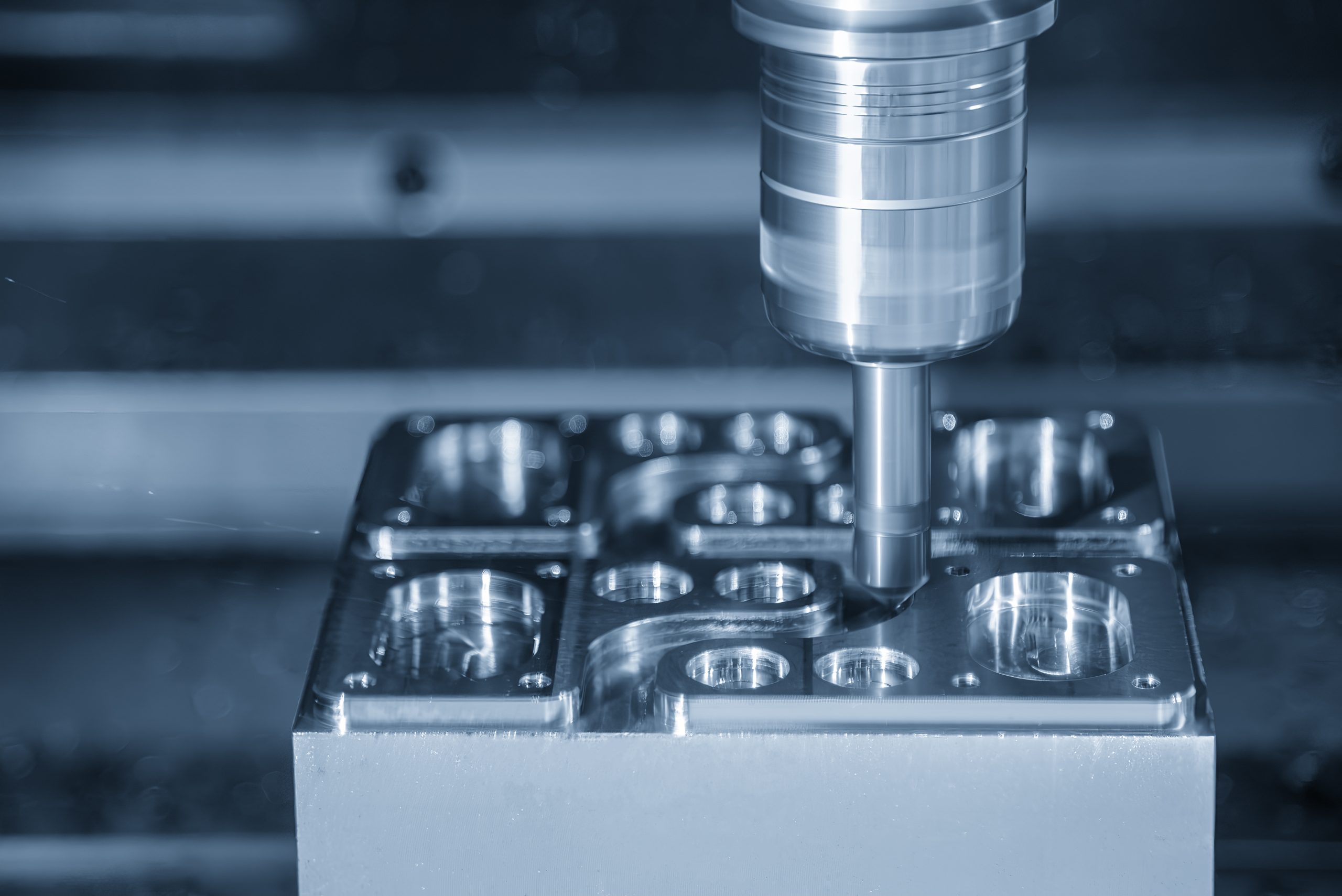

Comprehensive CNC Precision Machining Services & Products

WessDel delivers industry-leading CNC precision machining services, providing high-quality precision machining products and tailored engineering and manufacturing services. With decades of expertise, we serve diverse industries, including aerospace, energy, semiconductor, and medical devices, ensuring high-performance components that meet stringent industry standards.

Comprehensive Precision Machining Solutions

WessDel designed its advanced precision machining services to meet the most complex manufacturing challenges. We specialize in:

- CNC Milling & Turning: High-precision milling and turning for complex parts with tight tolerances.

- 5-Axis Machining: Increased efficiency and precision for complex geometries.

- Wire EDM Machining: High-accuracy cutting for hard materials and intricate designs.

- Custom Engineering & Manufacturing: Prototyping, reverse engineering, and full-scale production.

- Automated Control Panel Wiring: Custom panel wiring for industrial machinery

- Machine Rebuilding & Refurbishment: Extending equipment lifespan through expert repairs and upgrades.

- Contract Manufacturing: Scalable solutions for high-volume production needs.

Industry Applications

Our CNC precision machining services cater to critical industries, including:

Aerospace & Defense

We manufacture precision components for aircraft systems, satellites, and defense applications, ensuring compliance with stringent safety and quality standards. Our expertise in machining lightweight, high-strength materials supports the aerospace sector’s demand for durability and performance.

Energy & Power Equipment

WessDel supports power equipment manufacturers by producing high-precision components for DOE and energy equipment manufacturing. We specialize in parts for nuclear, renewable, and traditional energy generation systems. Our precision machining capabilities help optimize energy efficiency and system reliability.

Semiconductor & Electronics

We manufacture high-precision components for semiconductor processing equipment, supporting the industry’s miniaturization and performance optimization demand. Our ultra-precise machining ensures that semiconductor components meet exacting tolerances for cutting-edge electronic applications.

Medical & Life Sciences

We provide precision machining products for medical devices, surgical instruments, and laboratory equipment, ensuring compliance with industry regulations. Our machining expertise enables the production of intricate medical components that meet the highest standards of quality and reliability.

Advanced Machining Capabilities

WessDel’s facility has state-of-the-art CNC machines capable of producing intricate, high-precision components. Our capabilities include:

- High-speed CNC milling and turning for rapid, efficient production.

- Multi-axis machining for complex geometries that require extreme precision.

- EDM Wire machining technology for intricate components and high accuracy features.

- Water Jet cutting for precise and efficient production of sensitive materials.

- Comprehensive quality assurance with rigorous inspection processes and advanced metrology tools.

Commitment to Quality & Innovation

At WessDel, quality is at the core of our engineering and manufacturing services. We adhere to ISO 9001 and AS9100 quality standards, ensuring that every part meets the highest industry requirements. Our team continuously innovates, leveraging cutting-edge manufacturing technologies to optimize efficiency and precision. With our expertise in high-performance materials and advanced manufacturing techniques, we deliver solutions that meet the evolving needs of modern industries.

Partner with WessDel for Precision Machining Excellence

With a proven track record of delivering precision-engineered solutions, WessDel is the trusted partner for industries requiring high-accuracy machining and manufacturing. Whether you need custom precision machining products or full-scale production, we provide the expertise, technology, and commitment to exceed your expectations.

Product and Services FAQs

Contact Us for Precision Machining Products & Services

Contact WessDel online today or call (408) 496-6822 to discuss your CNC precision machining needs and discover how we can support your next project.