In precision machining and manufacturing, zero rework is the standard for success. Rework wastes time and resources, especially in mission-critical industries like aerospace, defense, and medical, where failure is not an option. At WessDel, our entire culture is built around achieving this standard.

For nearly 50 years, we have been the trusted manufacturing partner for the world’s most demanding projects by embedding a zero rework philosophy into our processes and technology. This philosophy is not just about efficiency; it’s about delivering absolute certainty in components that protect lives and power innovation.

The WessDel Difference: A Commitment to Quality Architecture

Our zero rework philosophy starts with a robust quality architecture that builds quality in, rather than inspecting it at the end. By designing quality into the process from the outset, we prevent defects rather than simply detecting them. Our AS9100D and ISO 9001:2015 aligned quality system is a guarantee of procedural integrity, crucial for our aerospace and defense clients. We ensure complete accountability through controlled revisions and full traveler traceability for every component, from raw material to final shipment. This process is verified by full inspections and comprehensive digital records, providing a permanent and verifiable assurance of quality.

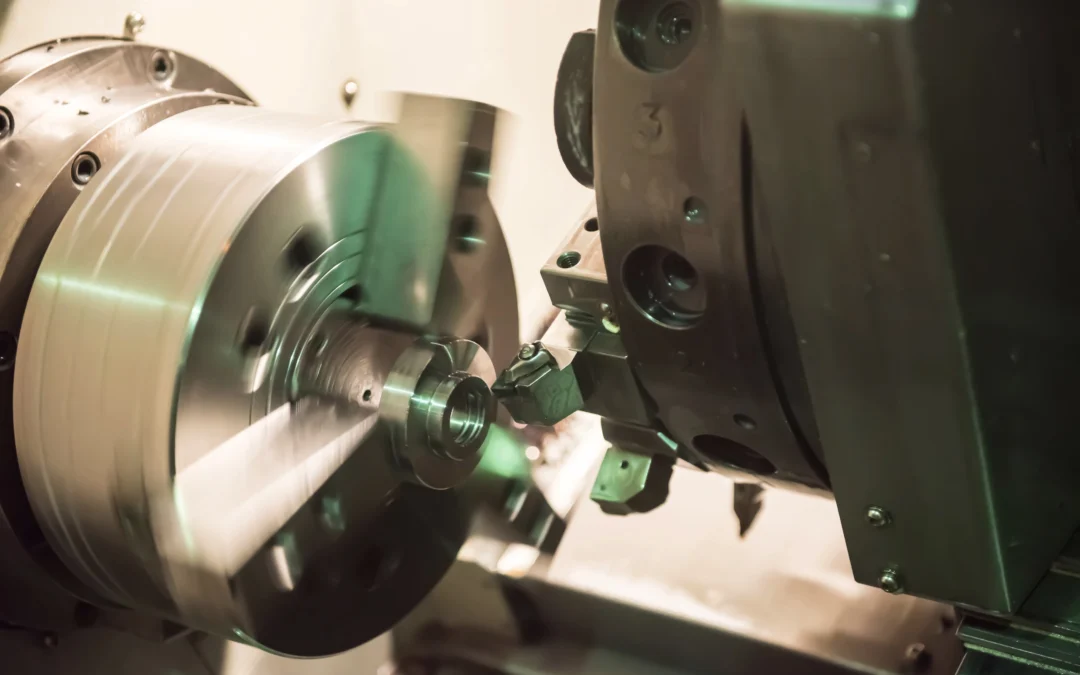

Advanced Machines and Methods for Unparalleled Precision

State-of-the-art technology is critical to achieving zero rework. Each piece of equipment is selected for its ability to produce complex geometries with extreme accuracy in a single, controlled operation. Our 5-axis machining centers collapse multiple operations into one setup, eliminating tolerance stack-up errors and reducing lead times. For intricate, burr-free features, we utilize Electrical Discharge Machining (EDM), a non-contact process ideal for delicate parts. We also use waterjet technology for creating preforms without heat-affected zones, which minimizes material distortion and ensures the final component’s integrity.

Process Discipline: The Foundation of Flawless Execution

Advanced technology requires disciplined processes. We eliminate variability and ensure repeatability through data-driven methods like Statistical Process Control (SPC) on all Critical to Quality (CTQ) features, allowing us to correct deviations before they become defects. Machining sequences are locked down to preserve datums, and we implement mistake-proofing techniques to prevent common errors in orientation or setup. Our highly skilled machinists and engineers are trained to treat the process as law, ensuring no undocumented changes compromise a part’s integrity. This discipline is the foundation of flawless execution.

WessDel’s Execution Model: End-to-End Excellence

Our end-to-end execution model brings our zero rework philosophy to life. By providing a complete solution from machining to chemical processing and final assembly, we act as a single-source partner. This single point of accountability eliminates the communication gaps and quality inconsistencies that often arise when managing multiple vendors. This integrated approach simplifies our clients’ supply chains and gives us total control over quality. Our culture of continuous improvement, using ToC, Kaizen, and 5S principles, ensures we consistently deliver greater value. With a certified quality system and a proven aerospace pedigree, we have the expertise to execute the most demanding projects.

Contact us today for precision machining and manufacturing

Ready to partner with a leader in precision machining and manufacturing? Contact WessDel today to learn more about our custom machining services and our commitment to “zero rework.”