Precision manufacturing doesn’t end with a working prototype: it begins there. As projects move from proof of concept to production, every tolerance, process, and fixture must align to deliver consistent results at scale. This is especially important for industries such as aerospace, medical, and tactical equipment manufacturers, who rely on flawless components for critical applications.

Let’s take a look at how smart engineering and disciplined process control make that possible.

Define “Custom”

“Custom” isn’t solely about complexity; it’s about function. The goal is to translate unique performance needs into measurable specifications that guide every decision, from tooling to inspection. Ask what “tight fit,” “long life,” or “thermal resistance” really mean in measurable terms. For instance, for tactical equipment manufacturers, “long life” might mean surviving a million-cycle stress test, and “thermal resistance” could mean functioning perfectly in sub-zero or desert conditions.

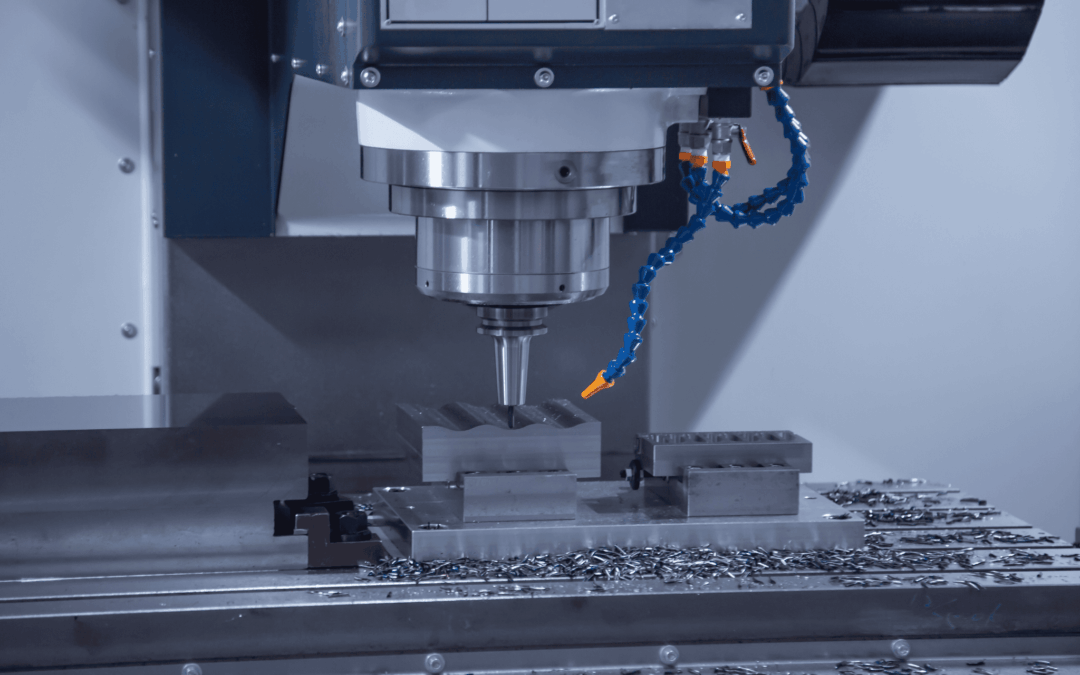

Then, choose machining processes that balance geometry, tolerance, and volume. Decide whether 4- or 5-axis CNC machining, EDM, or waterjet cutting best matches your design. Finally, document acceptance criteria early, including inspection plans, surface finish requirements, and certifications, so you and your supplier operate from the same clear standard of success.

By defining these parameters upfront, you minimize risk, prevent rework, and ensure that each part meets its intended function the first time and every time.

Prototype-to-Production Transitions

The jump from prototype to production requires stability and foresight. To scale successfully:

- Freeze key datums to lock in critical reference points.

- Optimize cycle times to maintain precision while improving throughput.

- Plan gages, fixturing, and part presentation to support operator efficiency.

- Build PPAP and FAI artifacts that remain valid through design iterations.

A structured transition shortens lead times, improves consistency, and preserves design intent even as production volumes increase. When every step is fully aligned, the result is a manufacturing workflow that is flexible and fully traceable, ready to scale without compromise.

Multi-Process Integration

Complex parts often demand more than machining alone. Integrating related processes early creates a stronger, more controlled workflow that maintains precision across every stage of production. For example, preforming parts with EDM or waterjet can protect thin walls and delicate features before final machining, reducing scrap and distortion.

Depending on material requirements, chemical and thermal treatments such as heat-treating, anodizing, or passivation can be integrated into the same process flow, maintaining traceability and reducing cycle time. When final assembly and functional testing take place on-site, engineers can immediately validate fit and performance, ensuring the finished product meets every design specification before shipment.

This level of integration not only streamlines communication but also strengthens quality control and reduces logistical overhead.

Contact WessDel in San Jose, CA, for Custom Machining Services

WessDel is a global provider of high-precision manufacturing engineering and custom machining services, supporting everyone from semiconductor leaders to tactical equipment manufacturers. Our 24,000 sq. ft., temperature-controlled facility includes multi-axis CNC, EDM, and waterjet systems, supported by program management that spans concept through finished assemblies.

With WessDel, you gain a single point of accountability for even the most complex projects, from prototype development to production. Call us at 408-496-6822 or fill out our online contact form to start planning your next project today.