Brazing is essential for assembling complex parts in aerospace, defense, and electronics. Choosing the right brazing method affects the quality and performance of the final product. Let’s take a look at the various brazing processes, design considerations, compliance standards, and how WessDel’s expertise in brazing services ensures high-quality results for demanding applications.

Choosing the Right Brazing Process

The first step in achieving a high-quality braze joint is selecting the right brazing method. Various processes cater to different material requirements, geometries, and operational environments.

- Controlled-Atmosphere Brazing (CAB): This method is ideal for oxidation-sensitive alloys. CAB ensures that the brazing process occurs in a controlled environment, preventing oxidation during heating, which is crucial for high-performance applications in aerospace and electronics.

- Dip Brazing: Best suited for intricate aluminum and AlBeMet (Aluminum Beryllium Metal) assemblies, dip brazing allows for the creation of uniform fillet joints. This process is particularly beneficial when joining complex geometries or when consistency across joints is required.

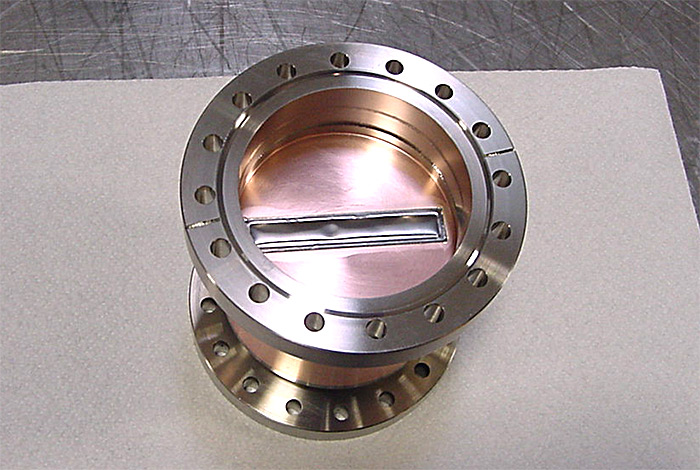

- Vacuum Brazing: This technique is perfect for high-integrity joints that need to be free of contaminants and oxidation. The vacuum environment ensures that the brazing is clean and precise, which is vital for aerospace and defense components that demand the utmost reliability.

Design for Brazing (DFB)

To achieve the best possible results, it’s essential to consider the design for brazing (DFB) principles. Proper design ensures strong, durable joints and minimizes potential issues like distortion or inadequate fillet formation.

- Capillary Clearances and Joint Lengths: The clearance between the parts being joined must be precisely controlled to ensure a strong bond. A well-designed joint, with the correct length and clearance, optimizes the strength of the final assembly.

- Fixtures to Control Flatness and Distortion: During the brazing process, parts can shift or distort. Well-designed fixtures help control flatness and prevent misalignment, ensuring a high-quality braze.

- Inspection Coupons and Witness Samples: Including coupons and witness samples in the design allows for validation of the brazing process. These samples can be inspected for quality assurance, confirming that the brazing meets design specifications.

Compliance and Verification

Brazing services for high-quality, mission-critical assemblies must adhere to strict compliance standards. WessDel follows industry regulations like ANSI, ASME, AWS, Mil-Spec, and RoHS to meet the demands of aerospace, defense, and other sectors. After brazing, we perform verification using non-destructive testing (NDT), microsections, and leak checks to ensure joint integrity. Additionally, we maintain full traceability and document furnace charts, offering transparency and accountability for each brazing cycle, ensuring the final product meets rigorous performance standards.

WessDel’s Brazing Capability

WessDel excels in brazing services for complex, mission-critical applications. Our capabilities include controlled-atmosphere, dip, furnace, and vacuum brazing for parts up to 48 inches. Operating under AS9100D and ISO 9001:2015 standards, we ensure aerospace-grade quality. With a proven track record in brazing beryllium and AlBeMet structures, we specialize in space and defense applications.

Contact WessDel for Brazing Services

When it comes to precision brazing for complex and mission-critical assemblies, WessDel stands out as a trusted partner. With a commitment to quality, compliance, and cutting-edge brazing techniques, we are equipped to handle even the most challenging projects.

Contact WessDel today to learn more about our brazing services and how we can help you achieve the highest standards in your assemblies.