While traditional methods like welding and soldering are common for joining metal components, many high-reliability applications need a precise process that minimizes heat-induced distortion.

That’s why our team from WessDel has highlighted the importance of advanced brazing services for you here.

Why Precision Joining is Essential in Critical Industries

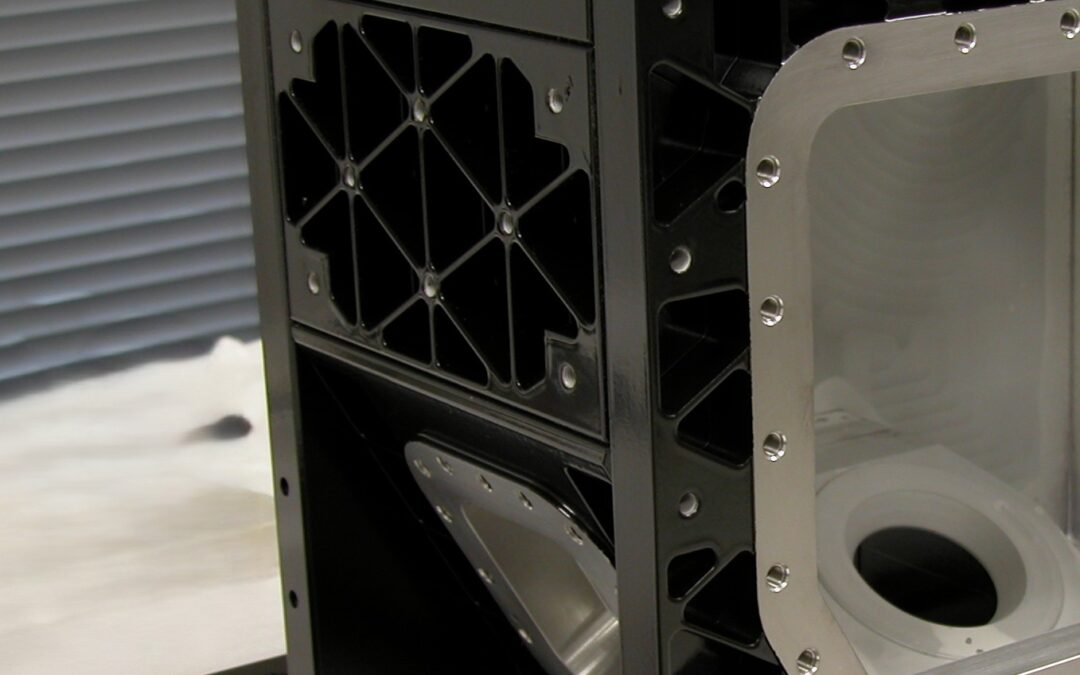

The most demanding industries require joints that are not only mechanically sound but also capable of creating and maintaining a perfect hermetic seal, often under severe operating conditions. Achieving this level of consistent performance relies on rigorous control over the assembly environment. This means using specific, high-purity filler metals and tightly controlled atmospheres to ensure the final assembly is contaminant-free and maintains the purity standards essential for high-stakes hardware.

The Foundational Principles of Vacuum Brazing

Vacuum brazing is done by performing the entire joining process within a highly controlled, high-vacuum atmosphere. This environment is crucial because it actively removes air and other gases that would typically cause oxidation when metal is heated. By eliminating these oxides, the base materials remain pure, which directly leads to a cleaner, stronger, and more reliable bond.

The process itself is driven by capillary action. As the assembly is heated, the specialized filler metal melts and is naturally drawn into the microscopic clearance between the parts. This flowing action creates a uniform, deep-penetrating joint, even across highly complex or intricate geometries. This capability is especially valuable for engineers who need to join dissimilar materials, such as metal to ceramic, or various metal alloys, significantly expanding design freedom without sacrificing performance.

Brazing vs. The Thermal Impact of Welding

Both brazing and high-vacuum welding are used to create permanent bonds, but their impact on the component’s structure is fundamentally different. Welding fuses the base materials by melting the substrate itself. This intense heat input often generates significant thermal stress, which can lead to part warpage or unintended changes in the material’s metallurgical composition.

Brazing operates at much lower temperatures, leveraging the melting point of the filler metal instead of the base material. This difference drastically minimizes thermal shock, helping to preserve the part’s precise, original dimensions. Unlike welding, which creates a localized fusion zone, brazing forms a continuous, smooth seal achieved through the controlled flow of the filler metal. For complex parts being produced in high volume, brazing typically provides a more repeatable and cost-effective method than the specialized, labor-intensive nature of precision welding.

Choosing the Right Specialized Joining Partner

When selecting a brazing partner, you need a supply chain expert with deep, in-house metallurgical and engineering knowledge to precisely manage the critical variables of time, temperature, and atmosphere. Consistent and uniform furnace control is paramount to guarantee that every single part in a production run receives identical thermal treatment.

Validation is equally critical. Post-braze processes, including non-destructive testing (NDT) and leak testing, are performed to verify that the final seals strictly adhere to specifications. WessDel offers advanced brazing services specializing in challenging materials like titanium and AlBeMet. These materials require specialized handling and expertise to ensure the high-purity, critical joints needed for hardware in the defense and semiconductor sectors are achieved every time.

Partner with WessDel for Hermetic and High-Purity Joining

Make sure your components consistently meet the highest standards. Contact the WessDel team online today or call (408) 496-6822 to discuss your specific thermal processing challenges and learn how our specialized brazing capabilities can become a reliable foundation for your next project.