Recent advances in materials, processes, and applications have significantly enhanced brazing capabilities. These innovations are important for aerospace, defense, semiconductors, and medical devices, meeting high demands for joint quality. Let’s explore developments in brazing suppliers, materials, advanced processes, automation, and quality assurance.

Advanced Brazing Processes for Complex Assemblies

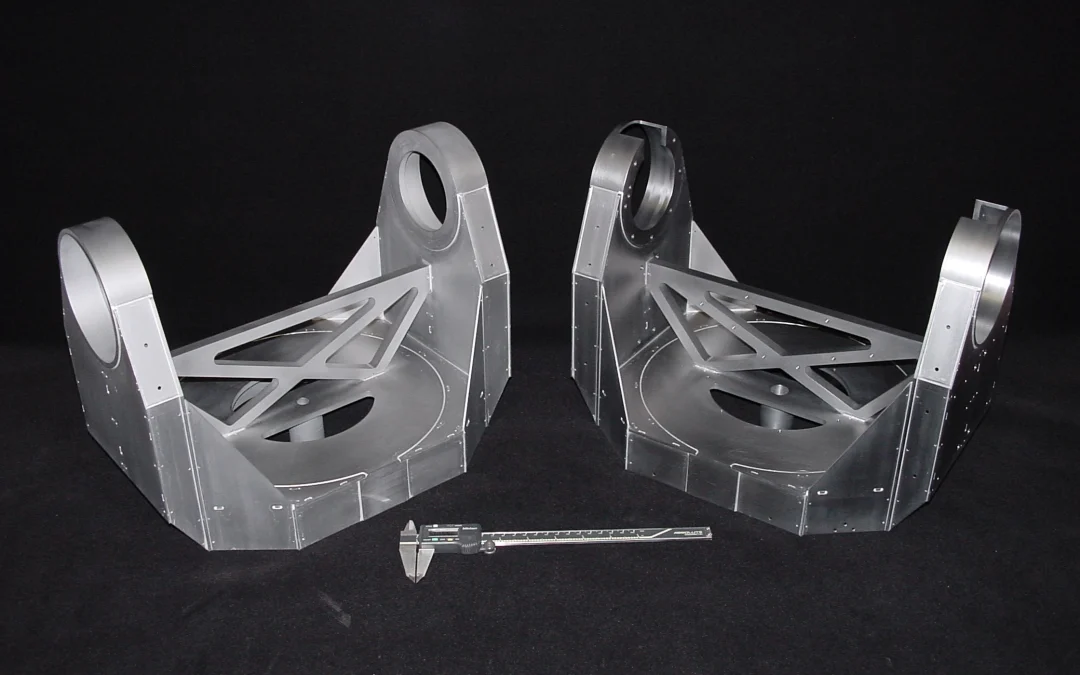

Modern brazing techniques, including vacuum and controlled atmosphere brazing, provide clean, oxide-free joints essential for aerospace and semiconductor parts. Active brazing is increasingly used to join dissimilar materials like ceramics to metals, enabling the production of lightweight, durable, and complex components where welding is not feasible.

Innovations in Filler Metals and Fluxes

Filler metals and fluxes have advanced significantly, with a focus on lead-free, high-purity alloys that meet environmental standards without compromising performance. Innovations in amorphous and active alloys improve bonding of dissimilar materials, while advanced fluxes support brazing ceramics and specialized alloys, boosting joint quality and reliability in demanding environments.

Automation and Digitalization in Brazing

Automation and digital technologies have revolutionized brazing, boosting precision and efficiency. Robotic systems handle complex parts accurately, minimizing errors and increasing output. AI monitors temperature, atmosphere, and heating rates in real time to optimize brazing. Digital simulations help engineers predict results, shorten development, and enhance designs, crucial for high-volume production and applications requiring flawless quality.

Brazing in High-Performance Industries

Aerospace and Defense

In aerospace and defense, brazed joints must be ultra-reliable under extreme conditions. Components like heat exchangers, fuel lines, and sensors often use materials such as beryllium and AlBeMet alloys that require precise brazing techniques to maintain strength and durability. Brazing enables the creation of lightweight, strong parts that can handle high temperatures, pressure, and vibration without failure.

Semiconductor and Electronics

Precision brazing is key to hermetically sealing semiconductor components and vacuum systems. High-purity brazed joints prevent contamination, which is critical for maintaining device performance and manufacturing yield. This is vital for sensors, advanced electronics, and semiconductor fabrication equipment.

Medical Devices

Brazing supports the manufacture of miniaturized, biocompatible assemblies used in implants, surgical instruments, and diagnostics. Specialized filler metals and processes ensure the reliability and safety required in medical applications, where failure is not an option.

Optimizing Brazing: Design and Quality Control

Effective brazing depends on design factors like joint clearance, surface finish, and material compatibility for proper braze flow and strength. Precise temperature and atmosphere control prevent defects, especially with sensitive materials. Advanced non-destructive testing—X-ray, ultrasonic, helium leak detection—ensures joint integrity and compliance with strict standards like AS9100D.

Advantages of Modern Brazing Technology

Brazing excels at joining dissimilar metals and metal-to-ceramic interfaces, which are difficult with welding. Lower temperatures reduce heat-affected zones and minimize distortion, preserving material properties in complex assemblies. Brazing offers an ideal balance of strength, hermetic sealing, and manufacturing cost, making it a preferred method for high-performance applications.

Contact WessDel to Work with One of the Leading Brazing Suppliers

Looking to elevate your brazing to the next level? WessDel delivers premium filler metals, fluxes, and consumables for vacuum, controlled atmosphere, and active brazing. Trusted by aerospace, electronics, and medical industries, our products ensure unmatched precision and strength. Contact WessDel now to transform your manufacturing quality and performance with one of the leading brazing suppliers.