Many companies see manufacturing as a straightforward process: send a design, get a finished part back. For complicated projects, though, this simple approach often results in missed opportunities for a better outcome. The difference between a part that simply...

Bob Dorricott

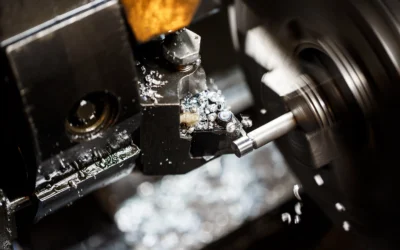

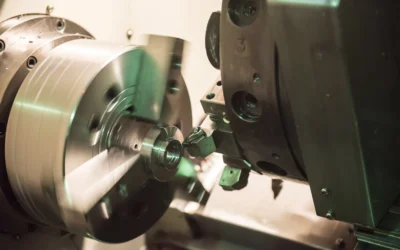

Leveraging 5-Axis CNC Turning Services for Complex Parts

Manufacturing technology has advanced significantly beyond basic 2-axis CNC turning. While traditional lathes are still great for simple cylindrical parts, modern engineering projects often require more sophisticated solutions. As components become more complex,...

Brazing Services: Hermetic Sealing for High-Purity Joints

While traditional methods like welding and soldering are common for joining metal components, many high-reliability applications need a precise process that minimizes heat-induced distortion. That’s why our team from WessDel has highlighted the importance of advanced...

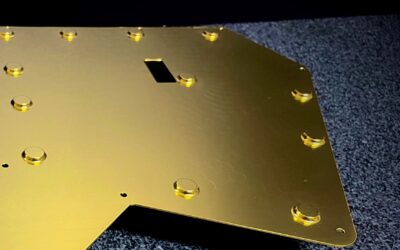

Advanced Aluminum Product Manufacturing: The AlBeMet Advantage

Traditional aluminum alloys have been reliable for decades, but critical applications in sectors like aerospace, defense, and semiconductor manufacturing require higher performance specifications that conventional metals cannot meet. As engineers pursue greater speed,...

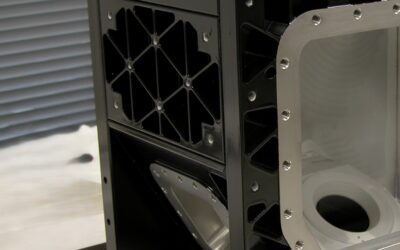

Advanced Precision Machining Demands for Exotic Materials

In aerospace, defense, optics, and other high-performance industries, components must meet extremely tight dimensional and functional requirements. When those components are made from titanium, beryllium, magnesium alloys, or other advanced materials, machining...

Precision Component Manufacturing: From Concept to Proof

In high-stakes engineering, whether aerospace, defense, or other mission-critical sectors, precision matters. Every micron, material choice, assembly step, and process decision can determine whether a part performs flawlessly under extreme conditions or fails when it...

Custom Machining Services that Scale from Prototype to Production

Precision manufacturing doesn’t end with a working prototype: it begins there. As projects move from proof of concept to production, every tolerance, process, and fixture must align to deliver consistent results at scale. This is especially important for industries...

Evaluating Brazing Suppliers for Aerospace-Grade Assemblies

In aerospace manufacturing, every joint must withstand extreme environments without compromise. The integrity of a brazed assembly depends not only on process precision but also on the supplier’s ability to meet rigorous standards across methods, materials, and...

Reverse Engineering Services: From Legacy Hardware to Production-Ready CAD

As manufacturing technology advances, sustaining legacy systems presents a significant challenge. Reverse engineering services are the definitive solution for overcoming component obsolescence, allowing critical industries, from aerospace to medical, to convert...

Precision Machine and Manufacturing: Building for Zero Rework

In precision machining and manufacturing, zero rework is the standard for success. Rework wastes time and resources, especially in mission-critical industries like aerospace, defense, and medical, where failure is not an option. At WessDel, our entire culture is built...