Brazing is essential in high-performance industries for creating strong, precise joints. But with advanced materials and complex designs, ensuring joint integrity is more challenging than ever. Let’s explore modern engineering strategies and emerging trends in brazing services that help overcome these technical and process-driven challenges in today’s demanding brazing applications.

Material Compatibility and Interactions

Joining advanced and dissimilar materials—such as ceramics to metals or beryllium to nickel alloys—presents complex metallurgical challenges. Brittle intermetallics may form at the joint interface, risking failure. Engineers now rely on specialized braze alloys with tight melting ranges and controlled diffusion to reduce erosion and liquation. Reactive metals like titanium, aluminum, and AlBeMet demand precise surface prep to remove oxide layers that hinder wetting. Techniques like ion beam cleaning, plasma etching, and mechanical abrasion are paired with vacuum or dry hydrogen atmospheres to ensure strong, flux-free bonds. These controlled processes are critical in aerospace and semiconductor manufacturing environments.

Precision Process Control in Complex Assemblies

Effective thermal management is essential in modern brazing, especially for complex or large assemblies. Uneven heating can cause warping, stress cracking, or poor filler flow. Engineers use multi-zone furnace controls, thermal mapping, and heat-flow modeling to maintain temperature uniformity.

Equally important is atmosphere integrity. In vacuum or controlled environments, dew point, oxygen levels, and gas composition must be precisely controlled. Continuous gas analysis and purging cycles are now standard for fluxless brazing, particularly in contamination-sensitive applications.

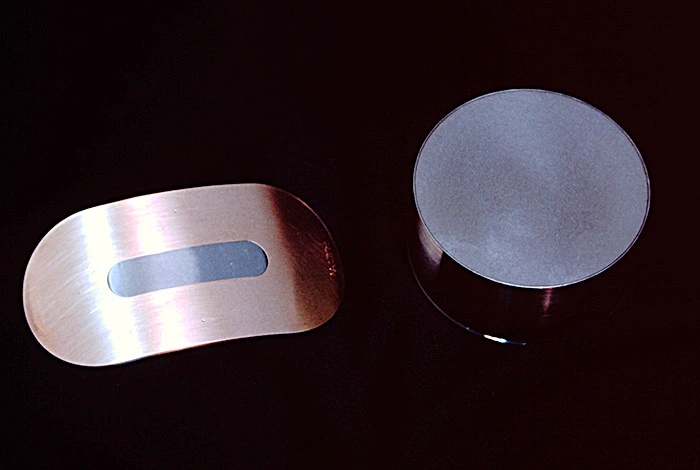

Filler metal placement is also optimized using pastes, foils, and braze tapes, supported by capillary modeling to ensure complete, void-free joint filling in difficult geometries.

Design and Fixturing for High-Integrity Joints

Design for manufacturability (DFM) now includes brazing-specific considerations. Engineers are incorporating joint geometries that control clearances based on alloy viscosity, optimizing self-fixturing features, and accounting for thermal expansion mismatches during the design phase to avoid residual stress after cooling.

Advanced fixturing solutions use thermally stable materials like graphite and molybdenum to maintain precise part alignment. Some facilities are exploring custom 3D-printed fixtures tailored to complex part geometries, improving heat transfer and mechanical stability during brazing cycles.

Predictive modeling through Finite Element Analysis (FEA) has become standard in high-reliability applications. These tools allow process engineers to simulate joint behavior, filler flow, and stress distribution, reducing reliance on physical prototyping.

Post-Braze Evaluation and Reliability

Engineers now rely on high-resolution NDT methods such as micro-focus X-ray, ultrasonic phased-array inspection, and helium leak testing to detect subsurface defects and verify joint integrity in sensitive components.

Residue removal is another critical step. The shift toward fluxless brazing eliminates the need for aggressive post-braze cleaning, which is especially important for vacuum devices and corrosion-sensitive materials.

When failures occur, root cause analysis involves SEM/EDS, metallographic sectioning, and mechanical testing to pinpoint causes like dewetting, intermetallic brittleness, or thermal fatigue—allowing for future process improvements.

Contact WessDel for Brazing Services

Facing a complex brazing challenge with advanced materials or tight specs? At WessDel, we specialize in solving the toughest joining problems with precision, innovation, and deep expertise in brazing services. Let’s tackle your next project—reach out to WessDel today.